DUST COLLECTOR BAGS

For all your baghouse requirements

- Polyester Dust filter bag

- Acrylic Dust filter bag

- Fiber glass filter bag

- Nomex/Aramid dust filter bag

- PPS dust filter bag

- PTFE dust filter bag

- P84 dust filter bag

Whilst our website has been prepared in good faith, Filtatrade (Pty) Ltd accept no contractual liability of any kind to any person in respect of its contents or any use made thereof, nor must it be assumed that any such use will infringe of any patent. All our information form no part of any contract with a customer, cub-contractor, importer, manufacturer. The data supplied on this website is typical and in no way reflects the final resultant values of the respective products.

For all your baghouse requirements

Dust collector cages support the shape of the dust collector bags and prevent them from collapsing on themselves. Just like filter bags, filter bag cages come in various shapes, sizes and configurations.

Our cages can be manufactured from the most Common Cage Materials Available:

• Galvanized Steel

• Carbon Steel

• Mild Steel

• Stainless Steel

• Titanium

Our cages are manufactured for high temperature, high moisture, acidic or other environments, according to all shapes, sizes, materials, coatings, lengths, applications and specifications.

For more efficient cleaning, we can also provide venturis for your dust collector cages.

Maybe you are working in a highly corrosive environment, we can provide and epoxy coating for your dust collector cages.

No matter your application, we can design and manufacture a cage to meet your needs.

Whether you're welding, grinding , cutting or sanding, we have an industrial dust collector fit for your specific needs.

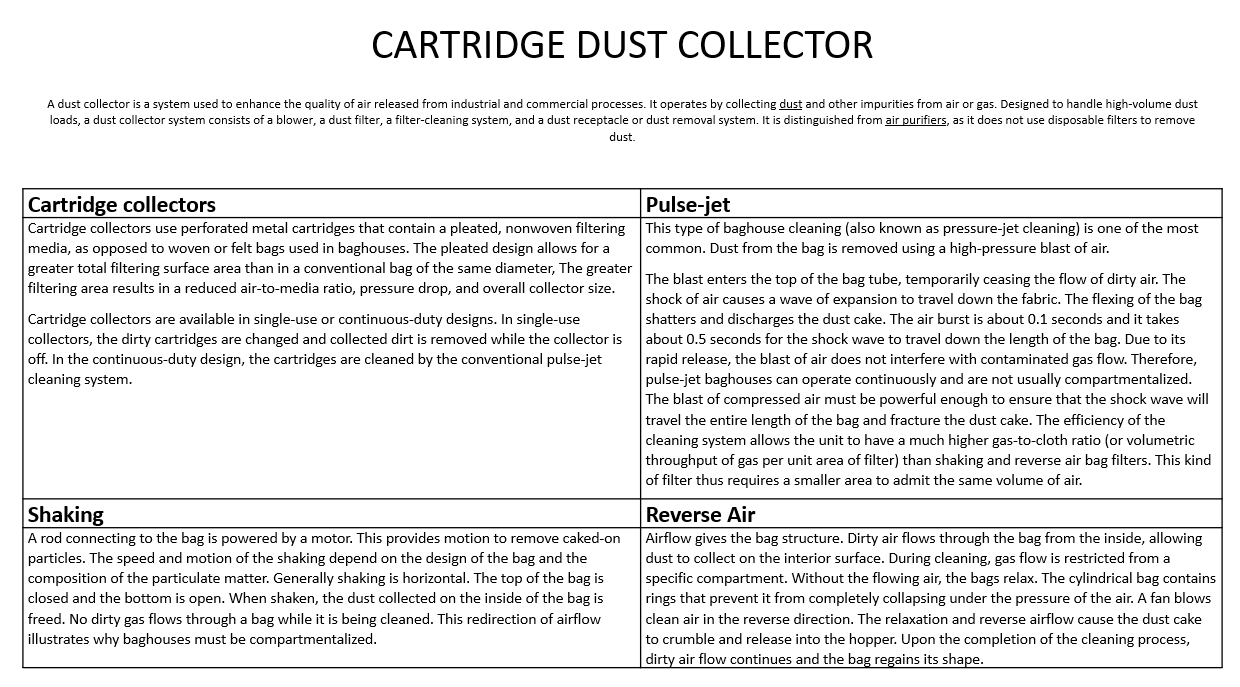

With many types and configurations available, cartridge dust collectors have become the go-to for general filtration needs for a variety of reasons, including:

• Compact size. Because pleated cartridge filters have a high filtering surface area, cartridge dust collectors are ideal for indoor, small- space operations.

• Highly efficient at collecting fine dust. Cartridge dust collectors specialize in filtering out very fine particulates, with efficiencies reaching as high as 99.97% at 0.3 microns.

• Versatile applications. Since cartridge filters can hold several different media types, a cartridge dust collector can be used in a variety of applications with a few simple cartridge changes.

• Long filter life. The pulse- jet cartridge filter cleaning method enables them to keep working efficiently for several months up to a year or longer depending on the application.

• Low maintenance. Cartridge filters are easy to access and can be replaced from the outside of the dust collector, minimizing physical contact with the collected dust and reducing downtime for filter changes. Since the filters last a long time, they don't need to be changed frequently.

•Low cost and lead time. Since cartridge dust collectors come prefabricated and custom-built due to their natural compact size, they cost less than some other dust collectors and can be delivered more quickly.

Free AI Website Maker